Aluminium is the ideal material to produce enclosures for buildings thanks to its great mechanical strength, its durability against corrosion, its long-lasting life span and the fact that it is a simple material. Moreover, aluminium offers a great deal of decorative potential because it can be lacquered or treated through a process of anodising.

At TECALUM SISTEMES we provide our knowledge about metalwork to you, gathered through our wide-ranging experience in the field, with the support of the aluminium profile extrusion factory Tecalum Industrial.

The raw materials, consisting of the cylindrical aluminium pipe, are purchased from internationally known suppliers who produce it by homogenised casting compliant with all rules, regulations and the highest quality standards, in lengths of up to 8 metres. A wide variety of alloys and sizes is available.

Tecalum Sistemes uses top quality materials that adhere to European rules to transform them into profiles.

Aluminium is a chemical element with the symbol Al and atomic number 13, belonging to the group of non-ferrous metals. It is the third most common element in the Earth’s crust, with aluminium compounds accounting for 8% of that crust in all. In its purest state, it is a soft material with little mechanical strength. However, when it is alloyed with other elements such as copper, silicon, magnesium or zinc, it acquires other qualities which make it very useful in metal engineering. Because of its low density (2700 kg/m³) and the fact that it is a good conductor of electricity and heat, alloying it allows us to give it greater mechanical resistance, to as much as 690 MPa.

In addition to this, it provide endless possibilities for surface finishes which also make it highly resistant to corrosion, as well as being easy to use in machining. This allows for countless adaptations and highly productive competitiveness.

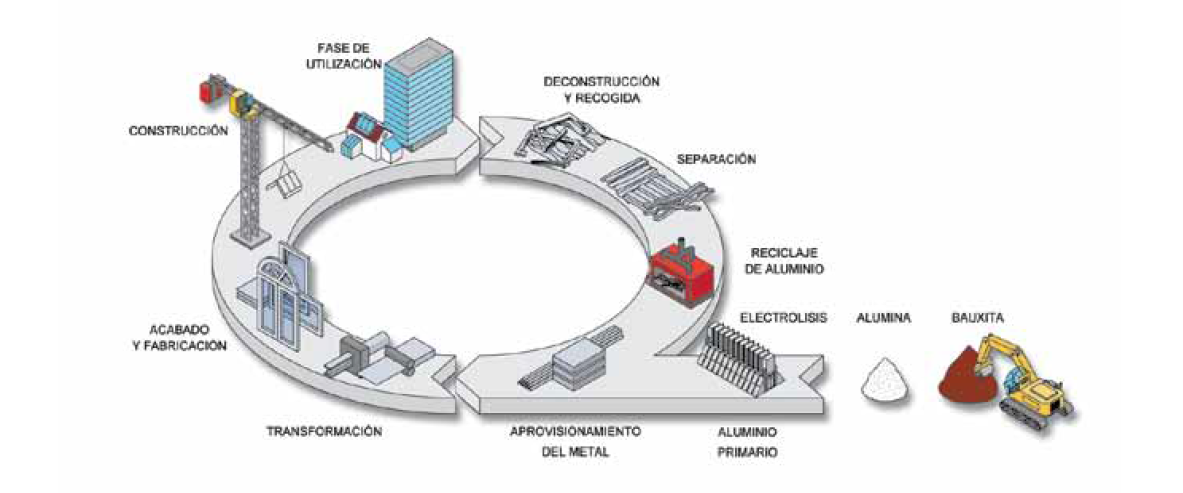

As a metal, it is extracted only in the form of the mineral known by the name of bauxite, which is first transformed into alumina and then into metallic aluminium, by electrolysis.

Due to all of this, since the mid-twentieth century it has been the most widely used metal second only to steel.

The main inconvenience in obtaining it lies in the large amount of electrical energy required to produce it. This problem is offset by its low recycling cost, its long useful life span and its price stability.